Breaking Ground in Cancer Research: How iHP Technology is Revolutionizing the Battlefield Against Cancer

In the relentless pursuit of a cancer-free world, researchers and scientists continue to push the boundaries of what’s possible. One of the most promising breakthroughs in recent years has been the integration of innovative Hydronics-based Power (iHP) technology in cancer research facilities. By harnessing the power of precision temperature control and efficient energy management, iHP technology is poised to revolutionize the way we approach cancer research, treatment, and ultimately, patient care.

What is Ionized Hydrogen Peroxide and How Does it Work?

Ionized hydrogen peroxide (iHP) was developed as a more advanced replacement for vaporized hydrogen peroxide (VHP). Unlike regular hydrogen peroxide, which might come in high concentrations, like 35 %, it uses a much lower concentration (7.8 %). This low-concentration hydrogen peroxide is activated through a cold plasma arc, generating hydroxyl radicals and •OH ions. These radicals are naturally occurring in the Earth’s lower atmosphere and provide a unique, highly effective method for pathogen elimination without relying solely on chemicals. This makes its use safer for both the environment and infrastructure.

The development of iHP traces back to the anthrax attacks in 2001. At the time, decontamination methods relied on high-concentration hydrogen peroxide and chlorine dioxide, which were effective but extremely destructive. They caused damage to buildings, peeled paint, and destroyed electronics and equipment. DARPA, the Defense Advanced Research Projects Agency, initiated research to find a better way to combat such biohazards. This led to the creation of iHP, which uses cold plasma to activate low-concentration hydrogen peroxide, providing a powerful yet non-destructive alternative.

What is Cold Plasma, and How Does it Enhance Hydrogen Peroxide?

Cold plasma is a state of matter used to activate low-concentration hydrogen peroxide. When hydrogen peroxide is passed through a cold plasma arc, it generates highly reactive hydroxyl radicals and •OH ions. These components are the active agents that kill pathogens effectively. Cold plasma is not harmful and produces a targeted activation process that enhances disinfection without destructive side effects.

Applications of Ionized Hydrogen Peroxide

Ionized hydrogen peroxide is very versatile and can be used in a wide range of settings. It is effective for eliminating viruses (e.g., H1N1, Norovirus, COVID), allergens, and pathogens in everyday environments like ambulances, daycare centers, and fire stations. It is also beneficial for homeowners and businesses looking for safe and efficient disinfection solutions.

Aside from being adaptable to different applications, this technology can disinfect spaces without high chemical concentrations, making it ideal for delicate environments. This is why pharmaceutical companies are among its primary users, taking full advantage of its unique features.

How is This Technology Used in Cleanroom and Pharmaceutical Facilities?

Cleanrooms and pharmaceutical facilities benefit greatly from ionized hydrogen peroxide, especially those that focus on maintaining sterile environments. iHP can be integrated into the building management systems within these facilities, helping to eliminate human error in the cleaning process. This ensures consistent, validated decontamination and allows facilities to maintain strict sterility standards without manual oversight.

Comparing iHP to Traditional Decontamination Methods

Compared to traditional methods such as chlorine dioxide or vaporized hydrogen peroxide, iHP is less destructive and uses lower chemical concentrations. Traditional methods were known for their harshness, often damaging infrastructure and causing destruction to equipment and materials.

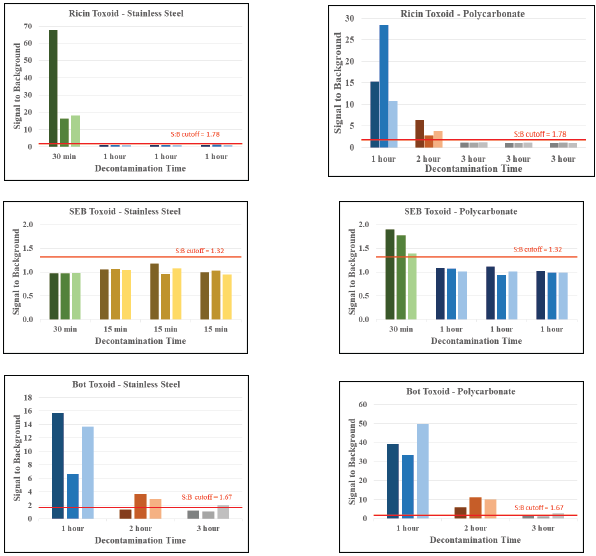

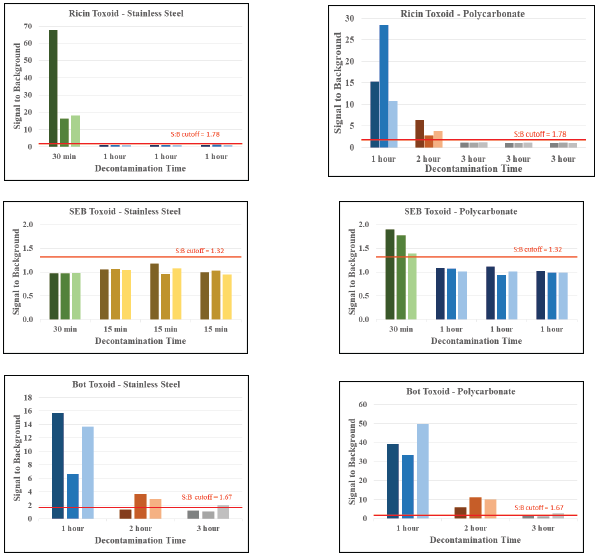

A case study demonstrates the effectiveness of iHP in decontaminating biological toxins. The test aimed to determine if iHP could contaminate biological toxins faster than VHP. The toxoids examined included ricin A chain toxoid, Staphylococcus enterotoxin B toxoid (SEB), and Clostridium botulinum A toxoid. The materials investigated were polycarbonate Lexan and stainless steel.

Practical Applications of iHP in Cancer Research Facilities

Disinfection of equipment and facilities in cancer research settings is a critical aspect of maintaining a sterile environment. iHP can be used to disinfect surfaces, equipment, and air, ensuring the highest level of cleanliness and reducing the risk of contamination.

Integrating iHP with building management systems ensures consistent and validated decontamination, allowing facilities to maintain strict sterility standards without manual oversight. This is particularly useful for companies that require high precision in maintaining sterile environments.

Benefits of using iHP in cancer research facilities include safety, efficiency, and effectiveness. iHP is a non-toxic and non-corrosive disinfectant that can be used in a wide range of settings, making it an ideal solution for cancer research facilities.

Future of iHP Technology and Its Potential Impact on Cancer Research

The future of iHP technology holds great promise for cancer research. As the technology continues to evolve, it is likely to have a significant impact on cancer research facilities, providing a safer, more efficient, and effective method for disinfecting equipment and facilities.

Practical considerations for implementing iHP technology in cancer research facilities include ensuring that facilities are equipped with the necessary infrastructure and trained personnel to use the technology effectively. Additionally, facilities should consider the cost-benefit analysis of implementing iHP technology and the potential return on investment.

Conclusion

Revolutionizing Cancer Research: The Potential of iHP Technology

In our exploration of enhancing cancer research facilities with iHP technology, we have delved into the intricacies of this innovative approach and its far-reaching implications. By harnessing the power of iHP (isothermal heat pumped) systems, researchers can create state-of-the-art facilities that provide a stable and reliable temperature control environment, essential for conducting precise and high-quality experiments. This technology has the potential to accelerate breakthroughs in cancer research, enabling scientists to better understand the complexities of the disease and develop more effective treatments.

The significance of integrating iHP technology into cancer research facilities cannot be overstated. As we have discussed, this technology offers a range of benefits, from improving temperature control and reducing energy consumption to enabling the use of sensitive equipment and promoting collaborative research environments. Moreover, the adoption of iHP technology can help bridge the gap between laboratory research and clinical applications, ultimately leading to improved patient outcomes. The forward-looking implications of this technology are vast, with potential applications extending beyond cancer research to other fields such as neuroscience, regenerative medicine, and synthetic biology.

As we look to the future, it is clear that the integration of iHP technology into cancer research facilities will be a game-changer. By harnessing the power of this innovative technology, we can accelerate progress in the fight against cancer and transform the landscape of medical research. The question now is not whether iHP technology will be adopted, but when. As we continue to push the boundaries of what is possible, one thing is certain: the future of cancer research has never looked brighter, and it is up to us to seize this opportunity and make it a reality.